ASC-508 Pass Knife Splitting Machine Instruction manual

ASC-508 Pass Knife Splitting Machine

Instruction manual

ASC-508 Pass Knife Splitting Machine

Operation Manual

ASC-508 type plate splitter instruction manual

First, Precautions:

- Before using this unit, please read this manual carefully. It will keep your machine running safely and smoothly.

- In any case, do not remove the protective plate around the blade under any circumstance, so as not to pose a danger.

- The machine is only designed for a circuit board with a pre-scored V-cut, do not use it for other purposes.

When operating this machine, do not wear too loose clothes. Long hair should be tied well to prevent it from being entangled.

- Plate mode tuning knob

- Power indicator and the origin

- Plate trip button

- High/low-speed switch

- Emergency stop switch

- Upper blade

- Upper blade baffle

- Height tuning knob of the upper blade

- Upper blade seat

- Lower blade

- Outer tray

- Lower blade baffle

- Side plate

- Manual knob screw

- Height limiter of the upper blade

Third, the technical instructions:

Maximum plate length of ASC-508: unlimited

Plate thickness: 0.2-5.0mm

Plate feeding speed: 300-500mm/s

Blade material: SKD61 high-speed steel

Operating temperature:10-35℃ Storage temperature: -20-50℃

Power supply:230V/110V,50HZ/60HZ,40W

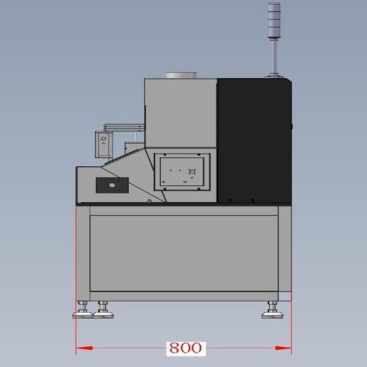

ASC-508 Dimensions:650mm*340mm*430mm

ASC-508 weight: 37KG

Fourth, the machine placement and preparation before use:

- Check the items in the box, including the following parts: the main machine, the instruction manual, the power cord, the foot switch, and the hex wrench for adjustment.

- Remove the machine bag, place the machine on a flat and sturdy workbench, and wipe off the anti-rust grease on the machine blade.

- To prevent static electricity from causing damage to the parts on the circuit board, the machine should be reliably grounded, such as the ground wire in the power outlet being reliable and effective, then when the machine is powered on, it has been reliably grounded.

- The outer pallet (11) is fixed to the machine with two tray fixing screws, and the tray is adjusted to the appropriate height according to the height of the parts on the circuit board, and the knob screws under the tray are manually locked.

- Plug the foot switch into the corresponding socket behind the machine, and power it on after confirming that the power supply voltage is correct.

Fifth, the machine adjustment:

- Confirm that the parts on the circuit board will not collide with the body and blade, and the relevant dimensions on the machine should not exceed the range of the parts on the circuit board in Figure 1. If the parts on the circuit board touch the blade, you can contact our company for special processing of the blade to avoid cutting the parts.

- According to the thickness of the circuit board, the height of the upper blade can be adjusted by adjusting the knob of the upper blade.

Sixth, speed adjustment:

Seventh, the daily maintenance of the machine:

The maintenance work during the use of the machine is quite simple, just keep the machine itself clean and regularly apply anti-rust oil to the upper and lower blades and the upper and lower baffles. A special person should be designated to be responsible for operation and maintenance, to ensure the accuracy of the machine, do not use or store it in a place where the temperature is too high or too low. (See Section 3)

Eight, blade replacement:

After long-term use of the machine, if the upper blade is damaged, release the adjustment knob fixing screw (16), and you can remove the damaged old upper blade; If the lower blade is damaged, remove the inner tray (13) and loosen the four screws on the lower blade to remove the damaged old lower blade.

- Instruction of the control panel:

- The high/low-speed switch is a speed control transfer switch, which is divided into slow speed and fast speed. When you start using it, set it to slow down and enable quick action after the staff is proficient. In this way, the quality of the sub-board can be guaranteed.

- The mode switch is standard. Divided into work is always foot or jogging, in the selection of all the foot pedal modes when not to go to the set of strokes will be the indicator light flashing alarm, must cancel the alarm in the continued work.

- Emergency stop is an emergency stop key, which is used when the cardboard is used.

- After the equipment is used, please turn off the power supply after returning the knife to the starting point position to ensure safety.

B、Operation Instructions:

- Connect the power supply and start the switch.

- Adjust the gap between the upper and lower knives, generally between 0.1-0.2mm, and the gap between the upper positioning knife and the lower cutting knife is generally the thickness of the PC board.

- The upper and lower cutting knives must be in the same plane, and the error cannot exceed 0.1mm.

- Eccentricity distance adjustment method.

- The working platform can be adjusted up and down.

- Set the cutting knife stroke and speed and set the method as the above adjustment method.

- Tap the foot switch, and test run several times, if there is no abnormality, it can be officially worked.

- Basic maintenance:

- After the work is completed, please turn off the power supply and remove the waste debris.

- Pay attention to the protection of the upper and lower cutting knives at any time.

- When it does not work for a long time, please remove the upper and lower cutting knives, and apply oil to protect them, please wipe them off before use.

- Pay attention to checking the tightening of each screw.

Repair card

Username: User address:

Machine model: User phone:

Date of purchase: Dealer stamp:

Notice to Users:

- Warranty for one year from the date of purchase, lifelong maintenance.

- The following conditions are not covered by the warranty:

(1) Machine damage caused by incorrect operation, negligent use, or natural disasters.

(2) The machine parts fail due to abnormal operation.

(3) A machine that has been disassembled or repaired by a non-technical person of the Company.

(4) Damage caused by the use of consumables or accessories other than the Company.

(5) Damage caused by the use of a voltage other than the company’s regulations.

- In addition to this guarantee, any other company and person issuing the relevant warranty card is not recognized by the company.

- Please deposit this card and the official purchase receipt and present them to our staff for inspection at the time of repair, which is valid.

- If the card does not have the trade name stamp and date of purchase, it will automatically expire.